Process Design for Separators

In association with Kirk Process solutions, Finepac offers process design and engineering services to develop optimised solutions for your separator vessels by optimising the design concept, vessel sizing and separator internal selection to meet the targeted performance.

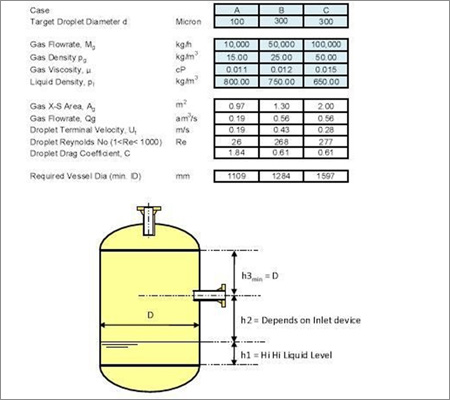

Appropriate process design and selection of internals is absolutely critical for proper

functioning of a separator vessel. Using the Sep - Calc software (Propriety Kirk Process

Solutions), the operating conditions are simulated for a variety of separator arrangements to

find the best solution.

After initially simulating the operating cases using standard separator design methods, we

then carry out a series of incremental designs, drawings upon a range of internals options to

evaluate the performance improvements finally optimising the overall vessel and nozzle sizing

to deliver an optimised performance and cost effective design to match the target

performance. The software accurately calculates a number of separator parameters that help

us develop an optimum solution including

- Full / partial vessel cross sectional areas

- Full / partial vessel volumes

- Multi- level liquid volumes and residence times

- Mist eliminator sizing estimation

- Sizing and selection of suitable inlet distributor

- Horizontal gas/ liquid separator sizing with nozzle velocities, pressure drops, residence times etc

- Vertical gas / liquid separator sizing with nozzle velocities, pressure drops residence time

- Coalescer pack sizing for enhanced liquid - liquid separation

For complex designs or applications requiring specialist internals we also offer design consulting services