Tri-ethylene Glycol Dehydration Systems (TEG)

In natural gas streams, water vapour needs to be removed to reduce pipeline corrosion and eliminate line blockages due to hydrate formation. In case of acidic gases are removed by amine treatment, the gas will be water saturated and will need to be dehydrated before it goes for further processing.

Glycol dehydration systems

Water vapour must be removed from natural gas to prevent pipeline corrosion and mechanical

damage to downstream equipment. The most commonly used method for this procedure

involves use of Triethylene Glycol (TEG) in a continuous process in which the water vapour is

absorbed from the gas under conditions of high pressure and moderate temperatures.

How Does It Work ?

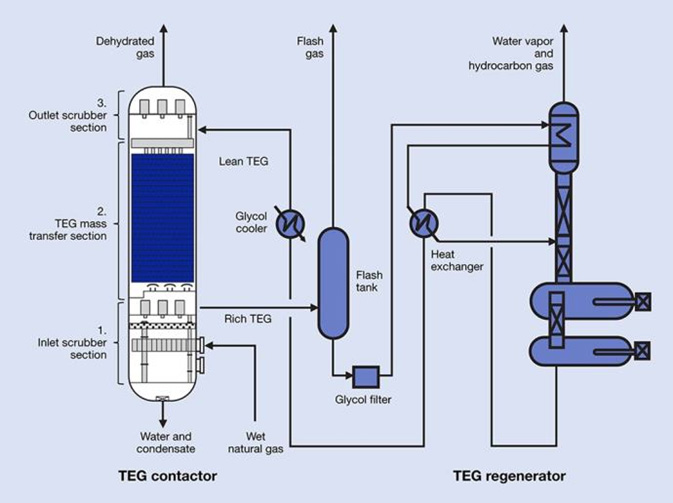

Wet gas enters the tower at the bottom and flows upwards. Dry glycol flows down the

tower from the top through the packing material to remove up to 10 ppm of moisture

in dry gas. Finepac structured packings are used for efficient moisture removal. The

dehydrated gas leaves the tower at the top and goes to other processing units. The

water rich glycol leaves the tower at the bottom and goes to a reconcentration

system consisting of a stripper and a regenerator. In this system Finepac random

packings are used. Water escapes as steam and purified glycol returns to tower where

it contacts wet gas again.

Finepac provides the following products for efficient moisture removal in glycol dehydration systems