Used Oil Refining

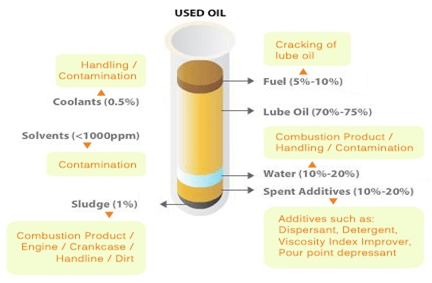

The re-refiner's job is to remove all the aforementioned contaminants and restore the oil to itsoriginal condition. The important point to note is that the technology used by Dominion Oil is virtually identical to that used to refine crude petroleum, the difference being that the level of contamination in used oil is much lower that in crude oil. Oil re-refining reduces greenhouse gases and heavy metal emissions when compared to burning used oil as fuel. Re-refining is a better way to manage used oil. It is easier on the environment and transforms oil into a renewable resource.

THE RE-REFINING OF USED OIL

The Key to greener planet is in your hands Move to waste oil recyclers.

Re-Refining Process :

- Dehydration Removes Unwelcome Water : Water finds its way into many used oil storage areas, so it’s the first thing we remove, using a process of evaporation. The water is collected, treated to be chemically and biologically safe and then discharged.

- Light End Recovery : Lightweight chemicals are extracted for reuse. With the water removed, the used oil goes to tall recovery towers where glycol and light fuels are separated and collected. By product: glycol is eventually reprocessed as a finished automotive grade product.

- Fuel Stripping : Heavier fuels are removed for industrial use. The used oil is now subjected to heat and vacuum processes which extract middleweight oils. By product: fuel for industrial heating.

- Vacuum Distillation : Heavy materials are reclaimed for multiple uses. The heaviest impurities are removed in a complex series of processes. The used oil is actually vaporized in an extreme vacuum and then condensed. Different materials are then separated from the oil. By product: heavy oil for industrial use, such as asphalt extenders, which are made from the heaviest residual material.

- Hydro Treating Removes Final Impurities : The remaining oil is treated with hydrogen to remove sulfur, nitrogen, chlorine, heavy metals and other impurities. This step also corrects any issues with odor, color and corrosion performance. The purified oil is then separated by weight.